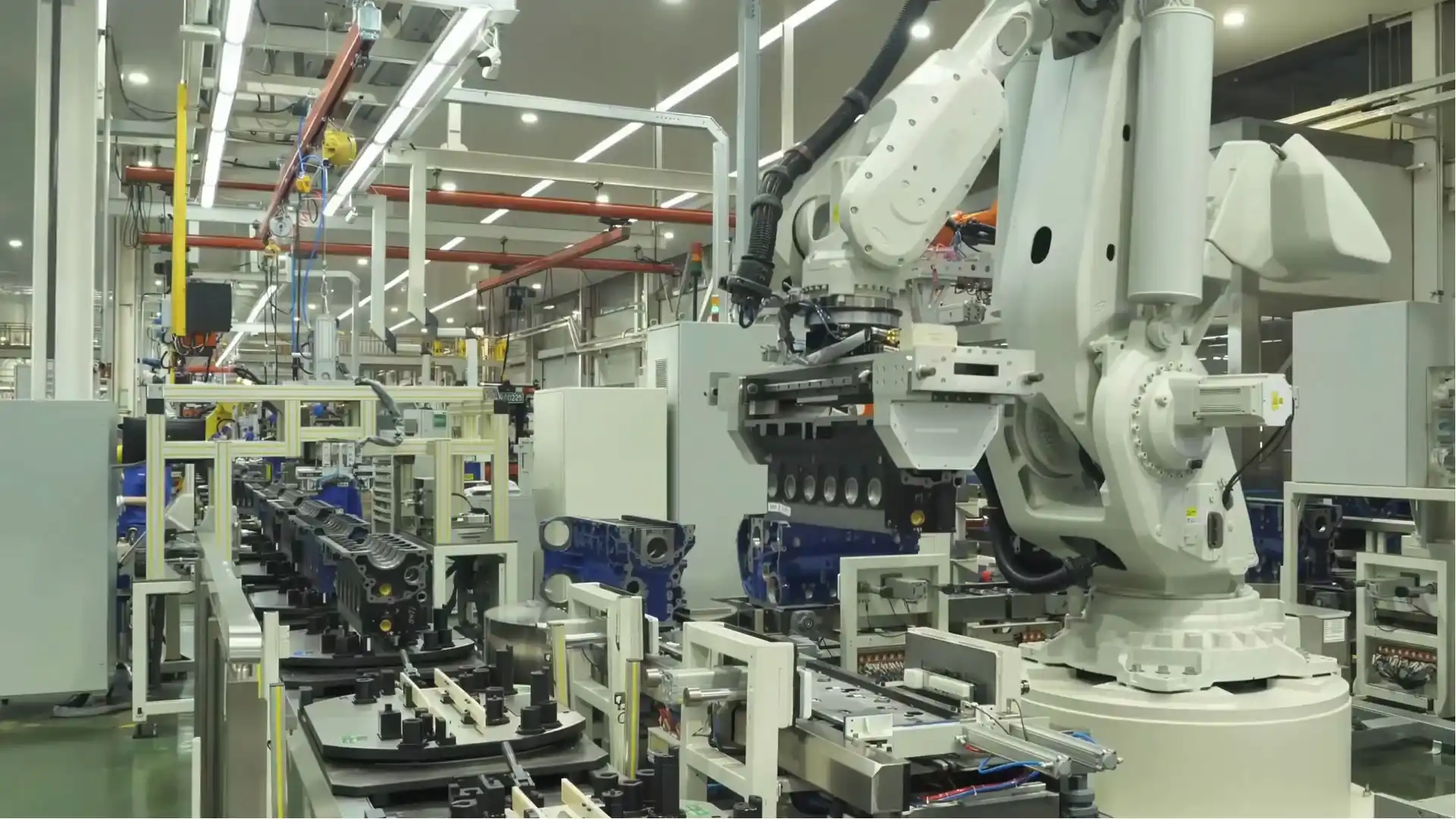

Engineering the Future of Machinery with Advanced Materials & Intelligent Sourcing

We supply custom-engineered metals and components, along with real-time sourcing solutions, driving innovation, productivity, and helping to create world-class manufacturing capabilities.

about us

The machinery and equipment industry is central to global manufacturing, supporting the automotive, construction, energy, mining, automation, and industrial engineering sectors. From heavy machinery and production systems to precision tools and automated lines, the sector relies on high-strength metals, engineered components, and wear-resistant materials that ensure accuracy, durability, and long service life. As India advances its manufacturing capabilities, the demand for certified materials, consistent quality, and reliable supply continuity is rising. Automation, component indigenisation, and new-generation equipment are driving the reliance on precision materials and efficient sourcing.

Metalbook powers the machinery & equipment industry with high-quality metals, precision components, and engineered materials designed for high-performance manufacturing. From structural parts and assemblies to tooling alloys and wear-resistant alloys, we provide materials that enhance durability, productivity, and operational efficiency.

Our offerings

Project Execution

End-to-end solar project execution from planning to commissioning.

Project Financing

Structured financing options to accelerate solar project deployment.

Marketplace

One platform to source certified solar components from trusted manufacturers.

Customized Products

Tailor-made metal solutions engineered for specific industry and project requirements.

Why Metalbook

Pan India Supply Network

Verified OEM partnerships with certified products

Transparent pricing & procurement intelligence

Digital tracking & supply chain visibility

One Stop Solution

Quality assurance & compliance

Tailor-made financing solutions for you

What do we do

01

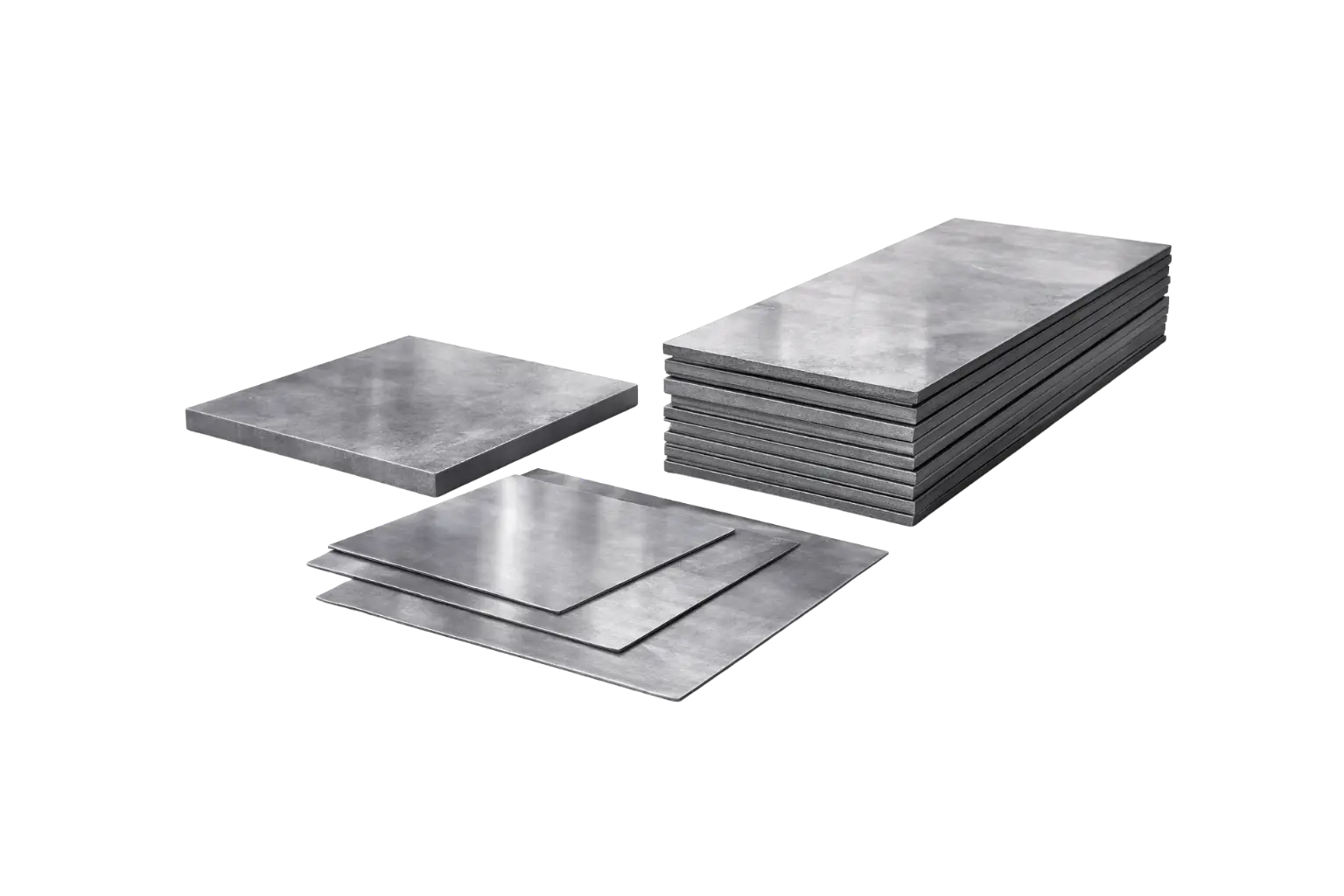

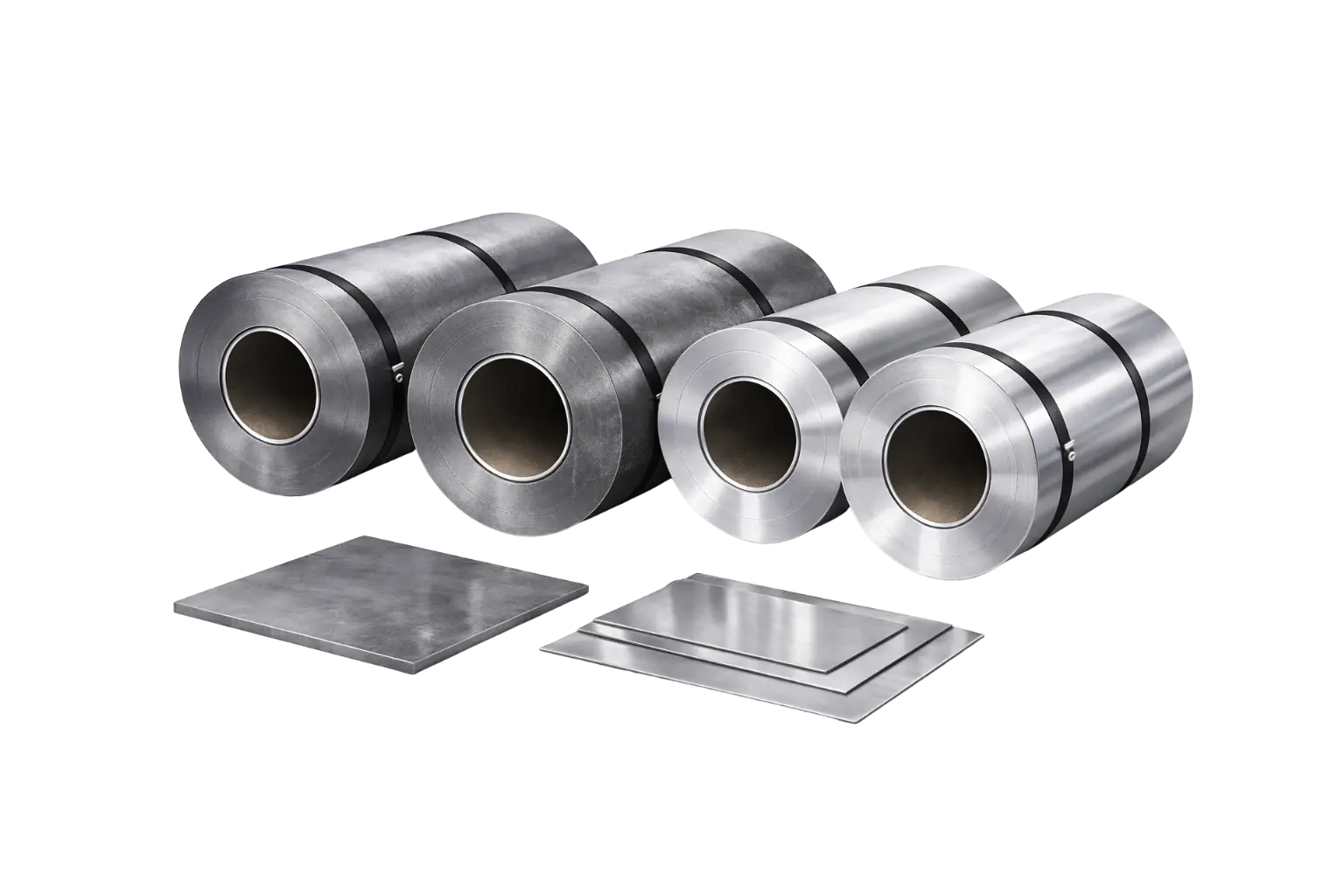

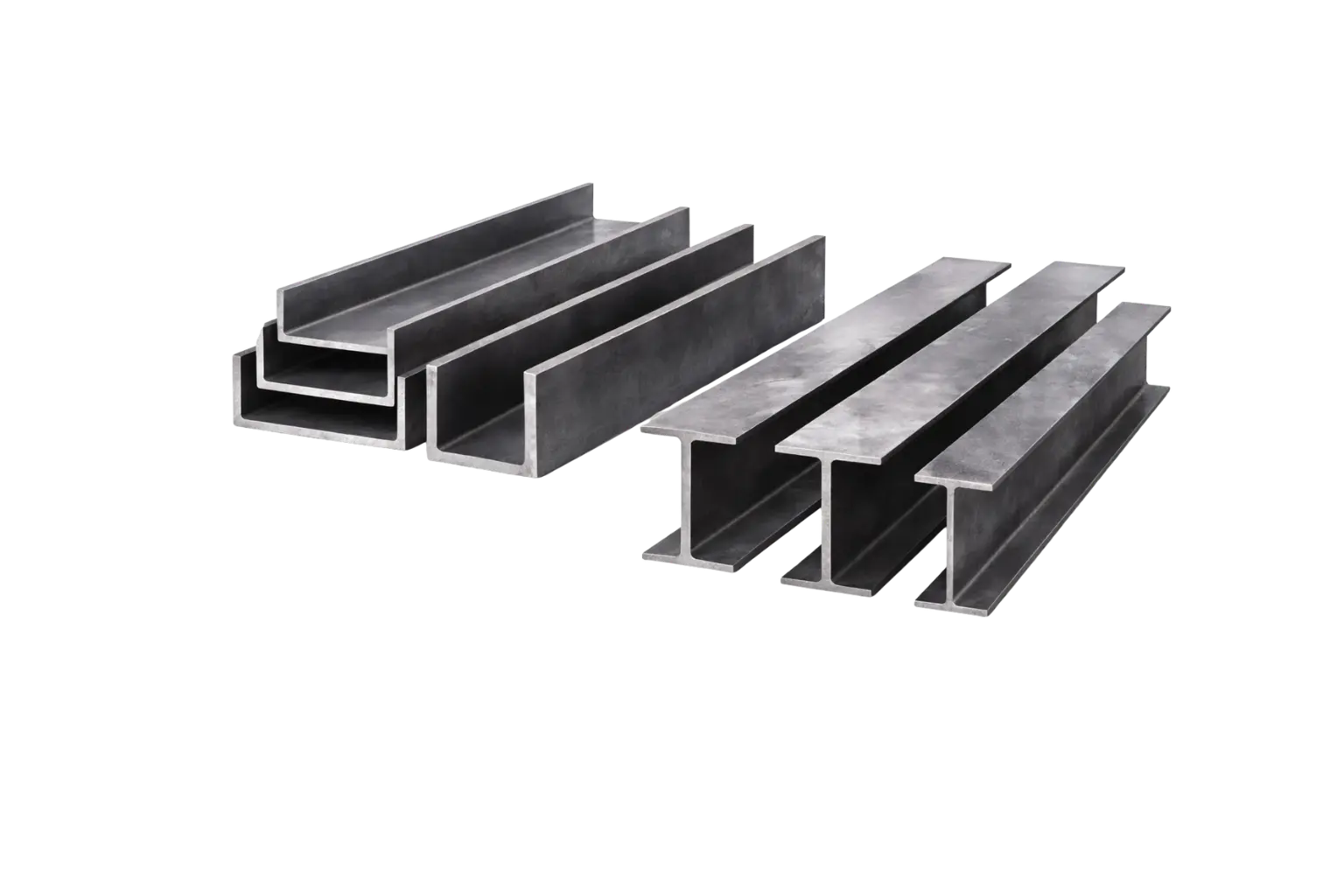

Supply High-Quality Raw Materials

We source essential raw materials from trusted manufacturers across India and globally. This includes steel plates, sheets, bars, beams, angles, channels, and coils. All materials come with proper mill test certificates and quality documentation, ensuring that your production processes start with reliable, factory-certified inputs.

02

Provide Metal Fabrication and Structural Elements

For more complex machinery assemblies, we supply ready-made fabricated components such as frames, supports, brackets, and structural parts. Our network of workshops specialises in producing these components according to precise specifications and drawings. We coordinate with these fabricators to produce components according to your drawings and specifications. and meet tight delivery schedules.

03

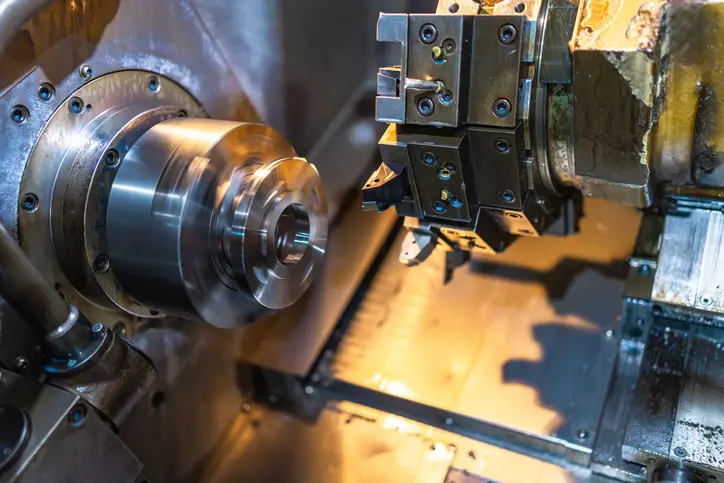

Metal Processing Services

Products

How Does Metalbook Help You

For Sellers

- Upload inventories such as structural steels, alloy steels, tool steels, plates, bars etc.

- Streamlined logistics, pickup and documentation to ensure proper dispatch.

- Faster movement to verified machinery OEMs, fabricators, and industrial manufacturers.

- Gain access to higher volume orders and recurring industrial demand.

For Manufacturers and Fabricators

- Receive consistent requirements, validated, quality verified, from suppliers.

- Search by type of Material using advanced Sourcing Filters (i.e., grade, thickness, hardness, tolerances, and shape).

- Reduce downtime/Increase Machine Utilisation through predictable sourcing.

For OEMs

Supply chain resilience through diversified domestic & global sourcing.

Quality assurance with complete traceability and documentation.

Lower sourcing risk through supplier verification and performance.

One-stop sourcing ecosystem for materials, components, and production-ready assemblies.

Get in Touch

Source materials faster through a digital, verified, and sustainable ecosystem.

Looking ahead?

Active Tenders in the machinery & equipment Industry

blogs

India’s Steel Exports Surge 20% in Apr-Jul FY’26 While Imports Tumble

India's steel exports rose 20% in Apr–Jul FY’26, driven by EU demand, while imports fell 29% amid safeguard duties and policy support.

Why is copper the world’s most important metal?

With anticipated growth in demand, it is expected that copper demand will be doubled by 2035, reaching 50 million metric tons. Demand will only be met to an extent of 80% through currently operating mines and announced projections of copper mining by the year 2030. There has been a 501% year-on-year growth in copper alloy sourcing, which embraces brass, bronze, and engineering alloys, as per Thomasnet. Copper finds great application in such basic things as electric motors, power transmission apparatus, renewable energy conveniences, wind turbines, electronic instruments, and heat transfer; it is a modern convenience that finds application in robotics, automation, computation, and rapid energy transmission. Copper is the most fundamental metal in the entire world, as it majorly serves varied sectors, construction having some uses in manufacturing. It has properties that confer on it the highest rank among materials used in electrical wiring, plumbing, and construction of industrial machines—however, contributing to economic growth around the world. According to the International Copper Study Group, worldwide copper demand is forecasted to hit 28 million metric tons by 2025, emphasizing its ascending relevance in modern industry.

Selecting the Right Stainless Steel Grade for Food Processing Equipment

The food processing industry is obligated to follow strict health and safety standards. With facilities increasing their use of automated machinery and components for higher output and faster speed, all of this equipment needs to be made of food-safe materials and finishes. Food-grade stainless steel has unparalleled benefits for the food industry. Food-grade stainless steel has many different grades, and the many ordinary characteristics of the steel above ensure compliance with the food safety and hygiene standards, making it suitable for a wide variety of food applications. In short, the food production and manufacturing industry uses food-grade stainless steel qualities to comply with food safety and hygiene standards.

Frequently asked Questions